Rosedale WWTP digester refurbishment

Client: Watercare

Refurbishing Rosedale’s digesters for long-term reliability

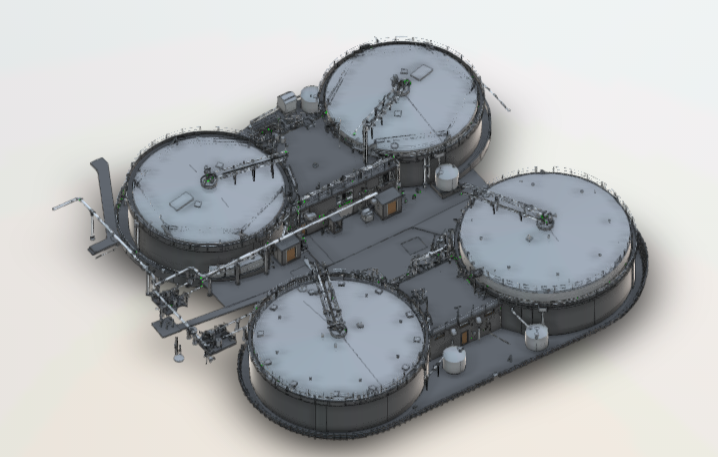

Watercare’s Rosedale wastewater treatment plant is one of Auckland’s most important infrastructure assets. Its four digesters are critical to processing biosolids safely and efficiently. But with the Northern Interceptor connection set to increase demand on the plant, all four digesters needed refurbishment to increase capacity and reduce the risk of outages.

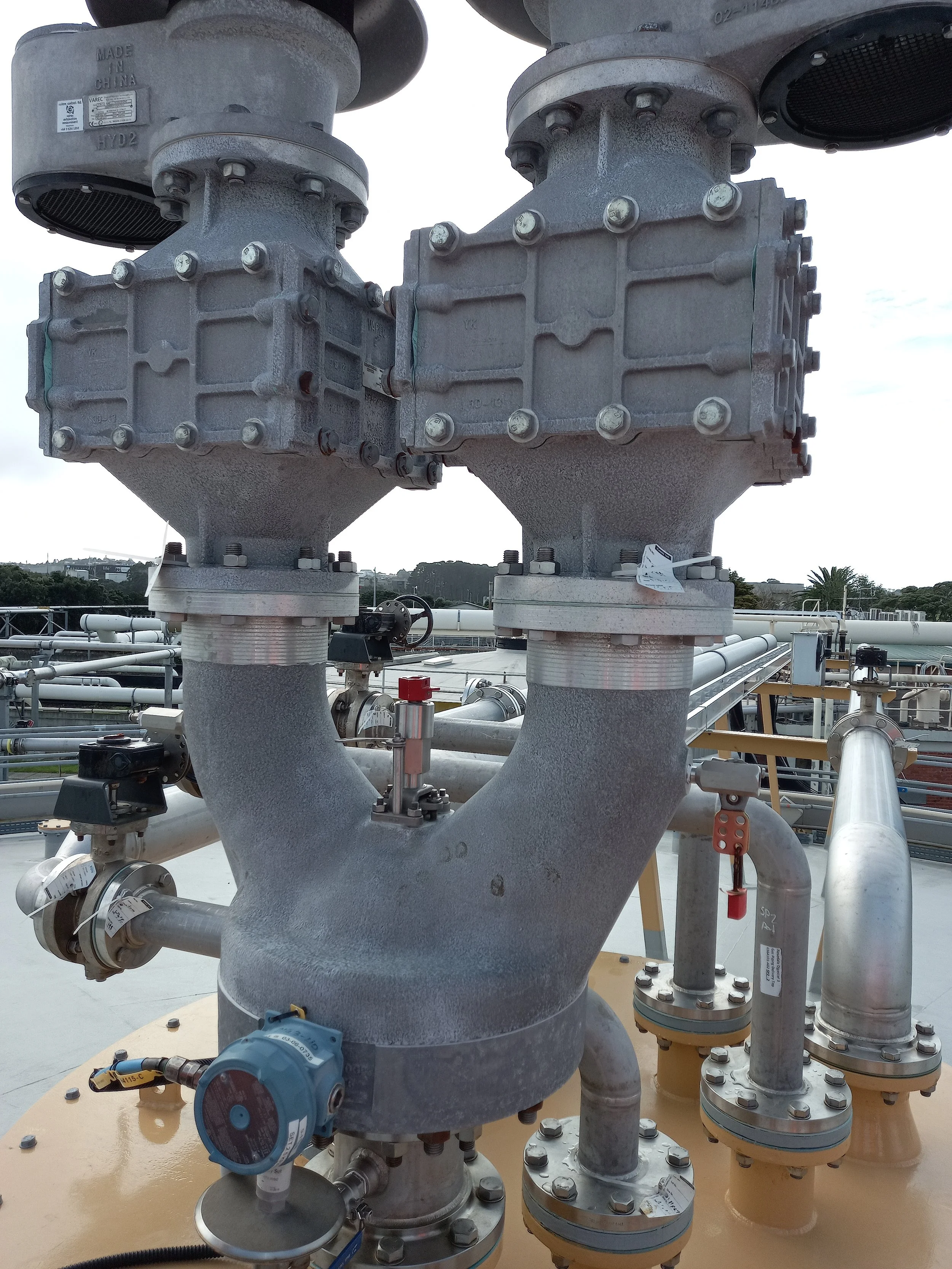

Digesters 3 and 4 were initially scheduled for refurbishment, but Digester 3 was quickly prioritised when operational and integrity issues were discovered. Corrosion of its floating gas holder cover (GHC) had compromised safety, reduced biogas capacity, and created a significant operational risk.

GRIT was brought in to carry out a condition assessment of the concrete tank and its 85-tonne steel GHC, along with all associated piping, access systems and equipment. From there, we worked closely with Watercare and the project team to develop a refurbishment scope that met the primary objective of extending service life by at least 10 years, targeting 15+ years of uninterrupted performance.

Dual approaches to access challenge

One of the most complex challenges was that visible damage was located inside the tank, in an area with no practical or safe access to execute repairs. GRIT approached the problem from two angles simultaneously: developing a lifting methodology and structural assessment for the 85-tonne cover to allow full inspection and refurbishment, while also modelling corrosion risk and investigating alternative coating systems that could be applied within the safe access limits. This dual approach gave Watercare options to weigh up potential cost, risk and operational impacts when deciding how best to proceed.

Refining the scope through collaboration

As the project evolved, GRIT’s role expanded from condition assessment and repair scoping, to broader design and project support. Our work included structural strengthening, waterproofing investigations, design of replacement elements, temporary works, corrosion monitoring systems and quality assurance oversight.

Throughout, we worked closely with Watercare’s project managers, operators, contractors and other consultants. Open communication, early risk identification and practical mitigation options kept the project on track. By focusing on details that often drive durability issues, we were able to propose improvements that maximise the digester’s performance over its extended service life.

Gaining insights for future improvement

Digester 3 returned to service in 2024 following a full refurbishment, giving Watercare confidence it will operate reliably for many years, supported by a clear inspection and monitoring plan.

Importantly, insights from this project are now being applied to Digester 4. By capturing real-time site data and refining the refurbishment approach, we now have a framework that will help reduce project costs, schedules and environmental impacts, while supporting Watercare’s strategic goal of operating these critical assets reliably into the future.