Jetty Fire Pump Gantry Repairs

Solving the unsolvable: Jetty fire pump gantry repairs

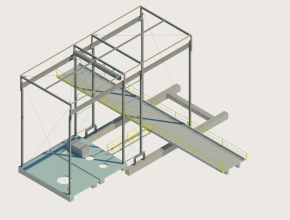

An inoperable fire pump gantry located on a jetty over the harbour at the Marsden Point presented a real problem. Used to maintain fire pumps, the gantry is a critical piece of infrastructure and needed to be returned to service quickly. But with structural issues making it prohibitively expensive to repair, and access issues preventing its removal, this was a truly challenging project that would require some real lateral thinking. Just the sort of problem the team at GRIT thrive on.

Repair and removal challenges

The fire pump gantry had been out of action for several years, after inspectors identified numerous structural issues. These included corrosion, bent members, and some main support columns being out of code for verticality.

Initially, the client considered removing the fire pumps serviced by the gantry, but the jetty access was not strong enough to support a crane large enough. Repair on the other hand would require full scaffold, cutting, welding and replacement of columns, making it prohibitively expensive.

GRIT takes ownership of this challenging task

With no obvious solution to the issue, the client was happy to hand over to GRIT. Our recognised strength in dealing with corroded and ageing structures meant the client had confidence our team could find a practical and workable solution. They knew GRIT would take ownership of the project and see it through until it was successfully resolved.

Breaking down the issues one by one

GRIT’s approach was to break down the issues and investigate each one, then develop a solution on a case by case basis. In this way, we turned an overwhelming task into several solvable problems.

With a lack of design drawings, 3D scanning was carried out to produce a model of the structure and determine the exact verticality issues. Using specialised software, we confirmed a series of bracing adjustments could be used to rectify the existing alignment issues.

Although the main lifting beam had previously failed code inspection due to alignment issues, GRIT established the mechanical gantry structure would tolerate a wider range of misalignment without creating a hazard or integrity issues. The improvements from bracing adjustment, combined with engineering judgement, were enough to certify the gantry for operation.

Corrosion issues were similarly investigated with the benefit of our extensive expertise in this area. Understanding current condition, structural utilisation, required service life and expected corrosion rates, we were able to specify structural repairs only where required, leaving those that were unsightly but did not limit the function or create a risk.

Scaffolding costs were slashed once it was determined corrosion wasn’t significant enough to justify a full recoat. This meant spot repairs could be designed for installation by rope access, for which GRIT teamed up with Vertech NZ to deliver a cost effective repair schedule.

GRIT also designed structural repairs to avoid any welding on site, and all cutting and drilling was completed cold. This eliminated the risk of sparks where pressurised hydrocarbons may be present, and also served to protect the pristine environment in which the refinery is located.

GRIT delivers a series of wins for our client

By challenging the need for demolition and digging deeper into the issues raised by inspectors, GRIT returned the existing structure back into full capacity service with minimal repairs. The reduction in scope significantly reduced environmental risk, safety hazards, time and cost, and resulted in a fit for purpose outcome. All these wins add up to significant value for our client.