Tank Foundation Design

Client - Red Stag TimberLow risk solution for a high risk zone

Boron tank foundation design and HSWA assessment for Red Stag Timber

An ongoing demand for treated timber from a buoyant construction industry gave Rotorua-based Red Stag Timber the opportunity to increase output from their plant. But to do so they needed an additional 45m3 storage tank for the hazardous substance Boron – used as a preservative in structural timber.

A challenging environment

As with any hazardous substance, strict regulations for storage protect the health and safety of people and the environment. So specialised expertise is required from the outset to ensure compliance with HSWA requirements. These included a suitable foundation and anchors for the tank that would prevent failure in a seismic event – a very real possibility in the geothermally active Rotorua region.

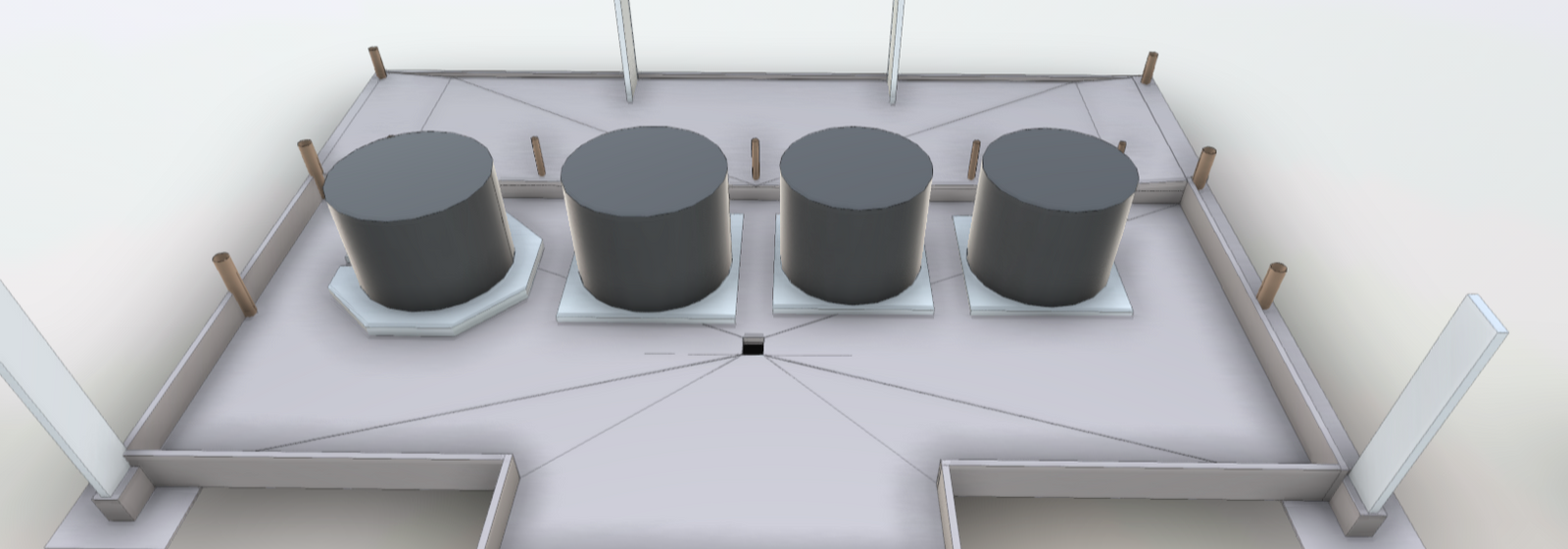

The new Boron tank would be located within an existing sealed bund area that is liquid-tight, providing secondary containment to prevent spills in the event of any tank or pipe failure. This first meant complex volume calculations were required to determine the capacity of the existing structures, and establish clearances for integration of the new tank.

It also meant any cutting or excavation of the existing concrete floor was best avoided, because of the difficulties of re-sealing the bund area designed to withstand corrosive substance spills.

GRIT: the clear choice for a complex project

With GRIT’s extensive experience in brownfields industrial projects, our understanding of HSWA compliance, and our proven track record of delivering fit-for-purpose, sensible solutions to complex problems, it was a clear choice for Red Stag Timber to work with our team on the integration of the new storage tank into their existing facility.

Using existing structural drawings and a site survey, GRIT generated a 3D model of the bund area to accurately calculate the available bund volume and confirm the new tank location and available clearance.

GRIT also completed a seismic analysis of the proposed tank. With seismic load demands calculated, our team designed an innovative seismic restraint system and supporting foundation to withstand operational and seismic loads.

As the tank area was a high-risk zone with hazardous substances present, GRIT also thought innovatively about how to minimise risk during construction. Our comprehensive analysis combined with innovative structural design meant we were able to eliminate concrete cutting or excavation that would create weakness or potential leak paths from the bunded area. Our design also minimised new reinforced concrete volume, thus reducing cost.

A workable and compliant solution

The result for the client was a simple, low risk design that could be installed safely within a hazardous zone, avoiding any demolition of existing paving or excavation. The new foundation simply anchored into the existing paving.

Detailed 3D modelling and existing containment structure analysis confirmed that minimal alterations to the existing structure were required for compliance with HSWA 2015.

All in all a successful outcome to a complex problem, as a result of innovative thinking and collaborative working between GRIT and the Red Stag team to provide safe, workable engineering solutions.